Bad weather happens. It is unavoidable. One must simply adapt and work around it. We had a fairly ugly windstorm coming in, so we had to take a break from building to prepare for it.

While we no longer live in the tent, it is our sole storage facility for the time being. Having it get broken or shredded in a windstorm would be very bad. There are many things in there that wouldn’t react well to rain exposure. It has been a source of great anxiety for me. It was time to address that.

The tent is 24′ long, which just so happens to be the same length as the roof. So when we ordered the roof steel, we ordered a few extra sheets for the tent. We considered fully covering it, and turning it into a permanent shed structure, but in the end we decided to half- cover it with the steel, put heavy-duty greenhouse plastic on the other half and have a 12x24x8 greenhouse. The plastic will wait until spring, but for now, we had the steel to put up.

Now, neither of us had handled roofing steel in our lives. We were the newest of newbies at this job. But we had been instructed on the basics. We knew we had to pre-drill the screw holes in both the sheet steel and the pipe frame, so we dug out the drill and gave it a go. And broke our drill bit within a very few minutes. Annoying. Off I headed to town to get a few more bits. I bought ones specifically for steel and headed home.

We broke all 4 of the new bits within the hour. ANNOYING. Back to town. Bigger bits this time.

The greenhouse will have 1 panel on the south side, 2 panels on the north. We got the one panel on and realized there is a problem. The steel was rigidly straight from pole to pole. The tent draped some, which means that water and snow would pile down in the dips and cause structural damage. We have to address that. We cut pieces of 2×4 to fit in between each set of poles, right at the top of the panel and screwed through the steel into the wood. This created a tight seam that I could cover with Tucktape. Ugly, but serviceable.

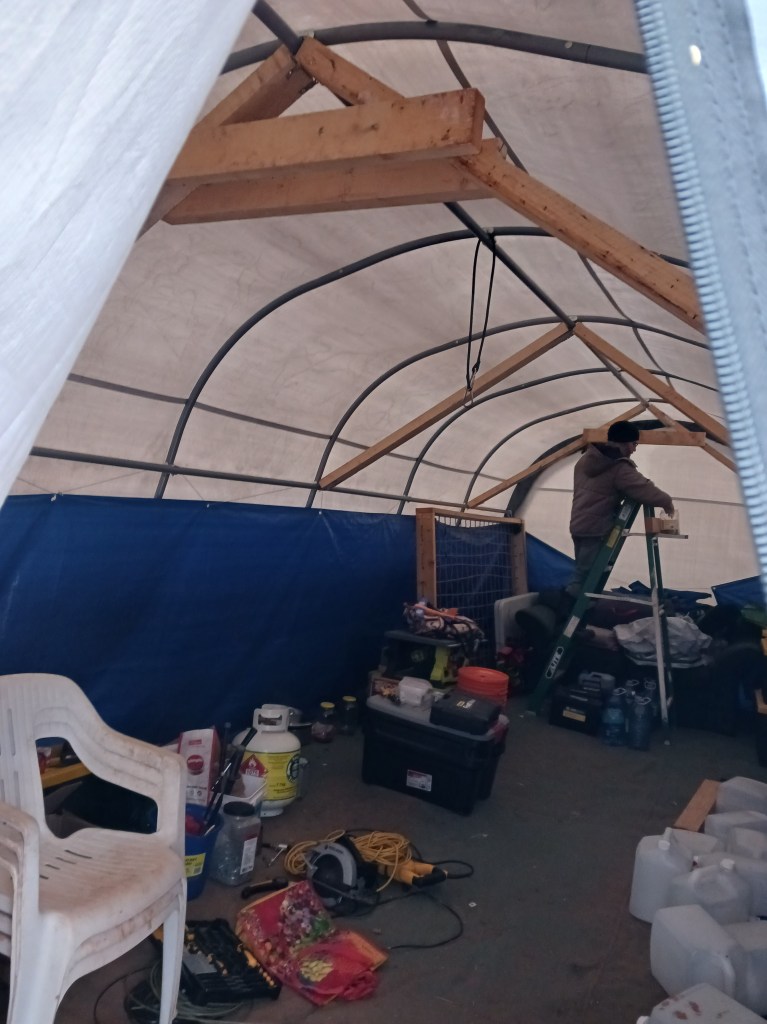

Once the steel was up on the outside (took a day and a half), we needed to address the major weakness of these tent garages — they tend to collapse under snow load. My sister in law had hers come down on her vehicle last year. I’d rather prevent the problem, if possible. I know from my research about roofs and rafters and trusses that a cross-tie is a major structural necessity. So we took a look at what we had available and created a rafter-and-cross-tie system of sorts.

It isn’t terribly easy to attach straight wood to curved steel pipes. We ended up using plumber’s strapping. It worked. I’m not sure how much load it can take, but it will at least help. We’ll keep the snow knocked off, of course, but mid-storm, a significant amount could end up piling on up there. It isnt pretty, but the creaking amd groaning we used to listen to in the wind has reduced significantly. Assuming it survives the winter, come early spring we will cut the tarps off and put the greenhouse plastic up